For mega-engineering applications, pump stations or pump sump are used to store and deliver water to the pumps. Therefore it is highly recommended to perform visualise study of the pumping station using CFD to take prior safety measures before it gets actual install.

From our decade of experience we have seen in most cases, the origin companies blame the pump supplier for low performance and low shelf life of the pumps. However, in actual practice, it is not always the pump that causes this problem but often flow towards the pump station.

CFD gives in detail flow information to understand the existing sump performance and carrying out iterative design modification make the sump to receive more uniform, vortex free/swirl free flow.

The given case demonstrates the application of CFD for the pumping station located at Goudse Hout, Netherlands. Characteristic of this pumping station is that water from both front and back side has to be pumped out. Water from the rear was brought forward using a bypass.

Upon completion, it was found that the required capacity of the pumping station was not achieved because one pump was not operating correctly and consumed excess energy. In addition, the pumps make a lot of noise, indicating the occurrence of cavitation.

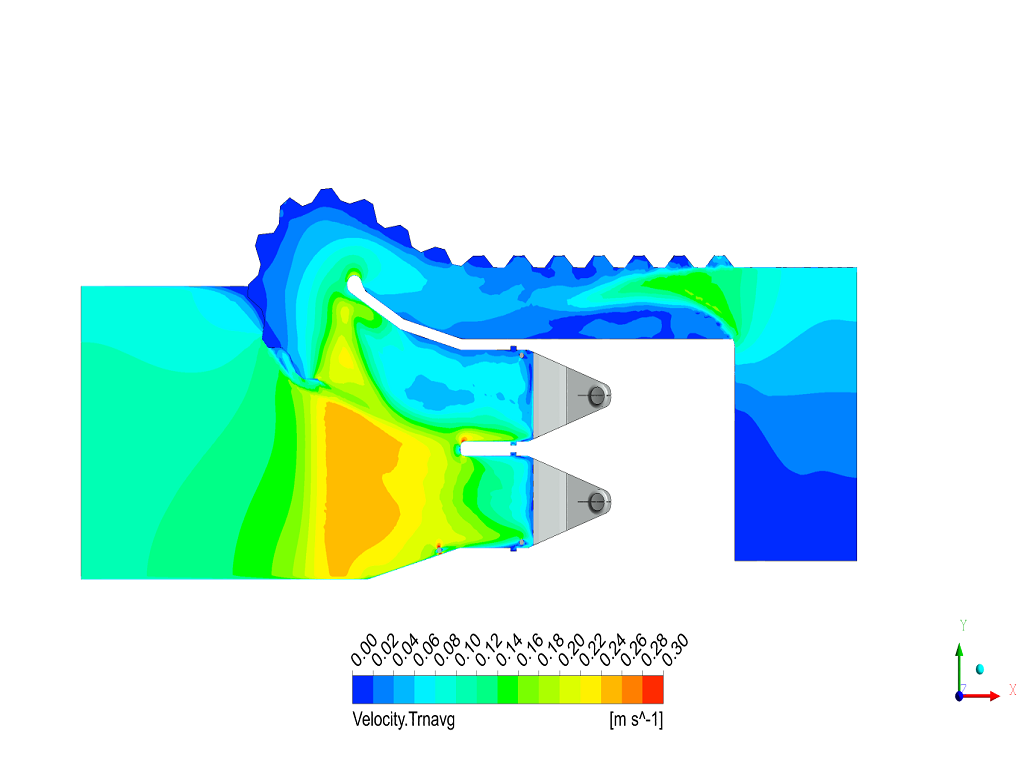

performing CFD calculations, Omnia-CFD has shown that the inflow of the pumps was not upto the mark. The simulations revealed that due to the construction chosen, large-scale rotations were generated in front of the pumps, which caused them to not operate at their optimal level.

With CFD, a number of new variants were then calculated. One of these variants was ultimately chosen because the deviations from uniformity were reduced by 75% and the fluctuations by 50%. In other words, the inflow was most uniform here. The corresponding streamlines are given below.

Based on these results, the channel was set dry, concrete was demolished and new concrete poured. During the restart the pumps remained silent and the desired capacity was obtained. As a result, the goals of the assignment were met so the contractor was finally able to complete his project.

At Omnia-CFD we have performed CFD analysis on multiple pimping stations / pump sumps and provided a satisfied solution to our client.

To know more about your pump station or pump sump contact us on info@omnia-cfd.com