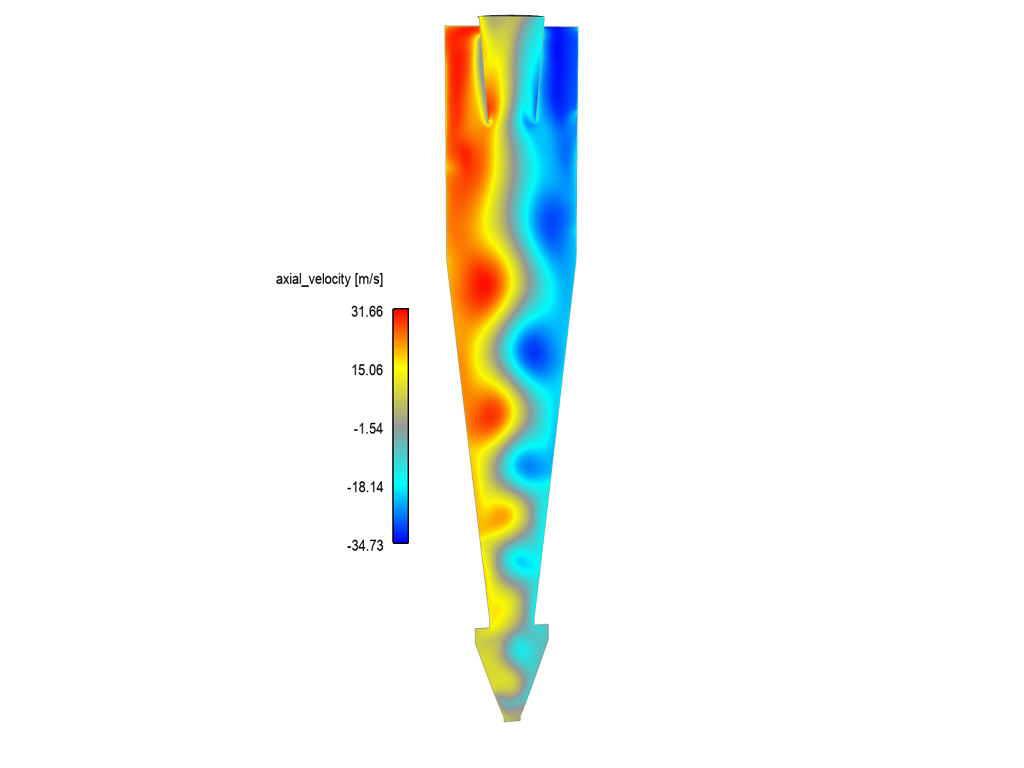

Cyclone separator removes solid particles from a particle laden gas stream. Cyclone separators separate particles and gas based on the forces that each solid particle and fluid experiences, such as inertial forces, surface forces, body forces. But mostly particles get separated on the basis of significant differences between the centrifugal forces acting on the gas and solid particles.

The final powder product is separated from gasses in cyclone separator, but before solid powder gets separated it takes a significant amount of operating energy and expense in evaporators, heat exchangers, spray dryers used in food, pharmaceutical, chemical and other process industries.

If you can’t separate your final powdered product from the gas of particles, the entire process is a waste of time, energy, and money.

How CFD simulation improves Cyclone Separator?

- CFD simulation helps you to understand the flow behavior inside the cyclone separator

- CFD analysis let you know the separation efficiency for the powdered particle for different particle size and density

- Customer can perform different variable analysis study such as cyclone velocity, diameter, cone barrel height etc.to get more reliable cyclone design before the manufacturing and installation

- One can know the cause of vibration and noise in a cyclone separator

At Omnia-CFD we have performed CFD analysis on various cyclone separators with different configurations and provided a satisfied solution to our client.

To know more about your cyclone separator contact us on info@omnia-cfd.com