CFD

What is CFD?

How does CFD work?

What are the benefits of using CFD?

What is CFD?

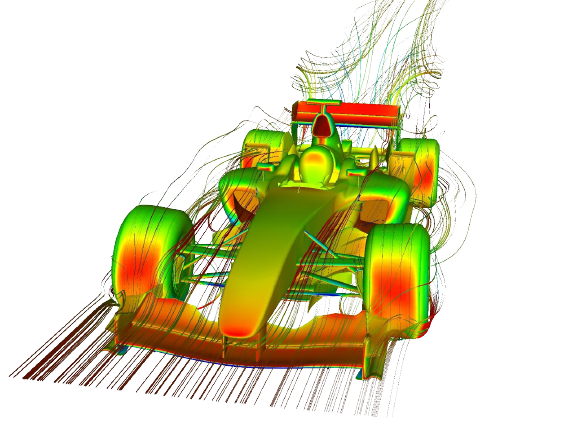

Computational Fluid Dynamics (CFD) is a branch of fluid mechanics that uses numerical methods and algorithms to analyze and solve flow related problems. CFD is a powerful tool that allows engineers to visualize flow behavior in complex piece of equipment before it get manufacture. These gathered information increase the possibility for improvement of product without any physical test and experiments.

How does CFD work?

CFD works by breaking down a fluid flow problem into smaller, more manageable parts. These parts are then represented by mathematical equations, which are solved using computers. CFD software allows engineers to model and simulate fluid flow, heat transfer, chemical reactions, and other related phenomena.

In general, CFD analyses cover 5 steps:

Step 1, Geometry Cleaning: The first stage of CFD analysis is geometry cleaning, which involves preparing the CAD (Computer-Aided Design) model of the system or object to be analyzed. This involves removing any imperfections, errors or gaps in the model to ensure it is a clean representation of the physical object. Geometry cleaning is an important stage as it ensures accurate simulation of the fluid flow around the object.

Step 2, Meshing: The second stage of CFD analysis is meshing, also known as discretization. This stage involves dividing the geometry into a finite number of smaller elements or cells to enable numerical analysis. The size and shape of the mesh elements can greatly affect the accuracy and efficiency of the simulation. The appropriate selection of mesh element and sizing is depend on the flow problem.

Step 3, Pre-Processing: The third stage is pre-processing, which involves defining the flow conditions and properties that will be used in the simulation. This includes specifying the fluid properties like viscosity, density, and temperature, as well as the boundary conditions such as the inlet and outlet velocity profiles. This stage also involves setting up the numerical model and selecting the appropriate CFD solver to be used for the simulation.

Step 4, Solver Execution: The fourth stage is solver execution, where the numerical equations are solved for each cell of the mesh. The equations that govern fluid flow are complex and require significant computational resources to solve. The solver execution can take from a few minutes to several days, depending on the complexity of the simulation and the computational resources available.

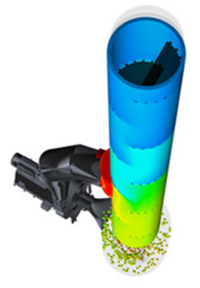

Step 5, Post-Processing: The fifth stage is post-processing, which involves analyzing and visualizing the results of the simulation. This stage involves generating 2D and 3D visualizations of the fluid flow patterns, temperature distribution, and other important parameters. Post-processing helps engineers and scientists understand the behavior of the fluid flow and validate the simulation results.

In summary, CFD analysis involves several stages including geometry cleaning, meshing, pre-processing, solver execution, post-processing, and result interpretation. Each stage plays an important role in the accuracy and efficiency of the simulation and requires a good understanding of the physics and mathematics of fluid flow.

What are the benefits of using CFD?

CFD offers several benefits to engineers and scientists. First, it allows them to visualize and understand fluid flow behavior, which can be difficult or impossible to do using physical experiments alone. CFD also saves time and resources by allowing engineers to test and optimize designs before they are built. Additionally, CFD can help improve product performance, reduce costs, and increase safety.

In general, CFD analyses cover 5 steps:

The first step is creating a simulation model. This is mostly based on a CAD drawing from a customer. In general the CAD drawing contains a lot of details that are obsolete for flow analysis. Therefore, some time must be spend on CAD cleaning

The second step is the mesh generation. The fluid domain has to be discretised using numerous volume elements. See the menu on meshing for some details.

Step three, is setting up the model, defining boundary conditions, selecting physical models, specifying multiphase settings, etc. If information for boundary conditions are lacking, it is recommended to perform additional measurements. See the Experiments menu for some details.

Solving the model is covered in step four. This is mostly done on Omnia’s server, or in the cloud, if CFD-models become too large, or if customers demand this.

Step five covers the postprocessing in which the results are summarized in qualitative figures and quantitative numbers. This step is considered as the most laborious step since it is not always simple to visualise the occuring phenomena in line with the customer’s expectations .

Get in touch with our team today to discuss your mission requirements.